Ƙwararren Ƙwararren Ƙwararren Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwa

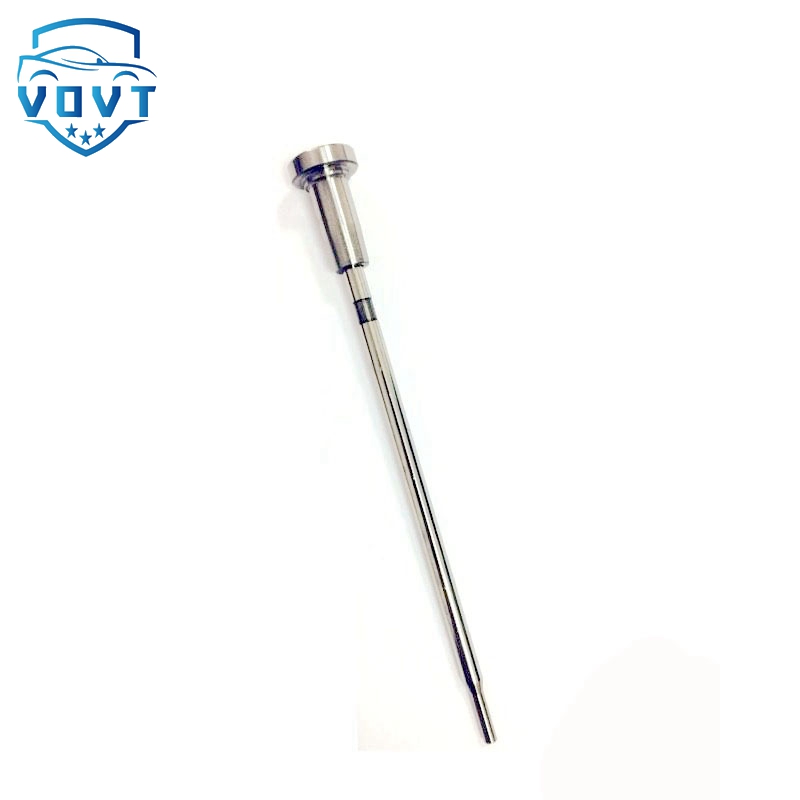

| Samar da Suna | Saukewa: F00VC01037 |

| Injin Model | / |

| Aikace-aikace | / |

| MOQ | 6 inji mai kwakwalwa / Tattaunawa |

| Marufi | Kunshin Farin Akwatin ko Buƙatun Abokin ciniki |

| Lokacin jagora | 7-15 aiki kwanaki bayan tabbatar da oda |

| Biya | T/T, PAYPAL, a matsayin fifikonku |

Ihanyar dubawa na allura bawul taro na man injector

(1) Gwajin matse wuya. Yi amfani da cakudaccen man fetur ko man dizal mai haske 20#, kuma a yi amfani da hanyar ragewa don aiwatar da wani benci na gwaji na musamman. Yayin gwajin, yi amfani da famfo na hannu don ɗaga matsa lamba zuwa 23-24 MPa, kuma auna lokacin matsa lamba don sauke daga 20 MPa zuwa 18 MPa. Sakamakon gwajin ya yi daidai da daidaitaccen samfurin yakamata a kwatanta shi da kewayon da ake buƙata.

(2) Gwajin hatimin wurin zama. A yi amfani da man dizal mai haske 20# akan benci na gwaji tare da na'urar tarawa, da farko dai a daidaita matsin allurar mai zuwa matsin da aka kayyade na 12.5 MPa, sannan a kara karfin mai da 0.1 MPa kowane 3 zuwa 5 s daidai da fara allura. Man, lura da ingancin hatimi, an ba da izinin zubar da ɗan ƙaramin mai, kuma diamita na ɗigon mai bai wuce 5 mm ba (wurin zama da saman ba sa niƙa juna) ko 3 mm a diamita (kujerun da kuma wurin zama). saman nika juna). Amma ba a cikin siffa mai kamanni ba.

(3) Gwajin fesa. Yi amfani da man dizal mai haske 20# akan benci na gwaji, daidaita ƙarfin allurar mai zuwa 12.5 MPa, sannan aiwatar da gwajin feshin tare da adadin allurar sau 40-80/min.

Ya kamata ingancin fesa ya dace da buƙatun masu zuwa:

①Man da aka yi masa allura ya kamata a gurbace, kuma kada a samu barbashi na mai da rashin daidaito a cikin gida wanda ido zai iya gani.

②Farawa da ƙarshen fesa yakamata su kasance a bayyane, kuma sautin ya kamata ya zama ƙwanƙwasa.

③Kafin fara feshi da kuma bayan ƙarshen feshin, ba a ba da izinin zubar da mai a ramin fesa ba, amma ana barin danshi.

(4) Duba kusurwar fesa. Duba tare da ido tsirara, kwatanta kusurwar fesa a ƙarƙashin matsin allurar man da aka yi amfani da shi akan injin dizal tare da samfurin, da kuma karkatar da ke tsakanin tsakiyar layin feshin injector na man fetur da tsakiyar layin mai ba shi da girma. fiye 4°30'. Ana lura da kusurwar mazugi a cikin 100 mm.

(5) Gwajin zamiya. A hankali tsaftace kuma shafa sassan da man dizal mai haske da aka tace. Lokacin da bawul ɗin allura ya kasance a 45° zuwa matsayi na kwance, cire bawul ɗin allura daga jikin bawul ɗin allura ta 1/3 na tsawonsa. Juya shi zuwa kowane matsayi kuma bar shi ya tafi. Nauyin kansa yana zamewa da yardar kaina ba tare da tsangwama ba.